In the past few weeks we've been championing aluminium and it's evidential usefulness both in the past, present and (potentially) future. Differentiating between the various metals encountered in our day to day is not something the average person thinks much about, but once you're more 'metal-literate', the world can look very different indeed! Thus, in this blog we're going to show you 5 of the most common applications of aluminium; perhaps in places you never would have quite expected.

#5 - Precision Tubing in motor vehicles, refrigerators, air conditioning, solar panels etc.

As we've explained elsewhere on the blog before, the use of pure aluminium is very rare in the commercial world. Usually the non-ferrous metal is mixed with other metals to create an alloy depending on the desired use. When this comes to precision tubing, the strong heat transfer applications allow it to be used extensively for the automotive, AC and solar market industries, as well as for carrying liquids or gases. It's been noted as being very similar to plastic in how it can be worked upon without breaking, and for being very widely recycled.

#4 - Power Lines

Aluminium's light weight and durability would make it an ideal candidate for transporting energy across long distances, but as a pretty poor conductor it needs to be mixed with the properties of copper (which is normally too heavy and expensive to do the job on its own), or better yet, boron. The ability to withstand corrosion and general lack of a need for a costly support structure is a plus, and the aluminium alloys themselves are often reinforced with steel - a true match made in metal heaven!

#3 - Rolled Aluminium products

One of the few explicit uses of aluminium in more common everyday use, by its more informal title tin foil is produced through the metalworking process of 'rolling', whereby sheet ingots are cast from molten billet aluminium, then re-rolled on sheet and foil rolling mills to the desired thickness (or lack thereof), or by continuously casting and cold rolling. Impermeable to oxygen and water, it can be used to not only cook food but also to keep it fresh as well, thus its a very rare day indeed in which you don't spot a bit of tin foil somewhere.

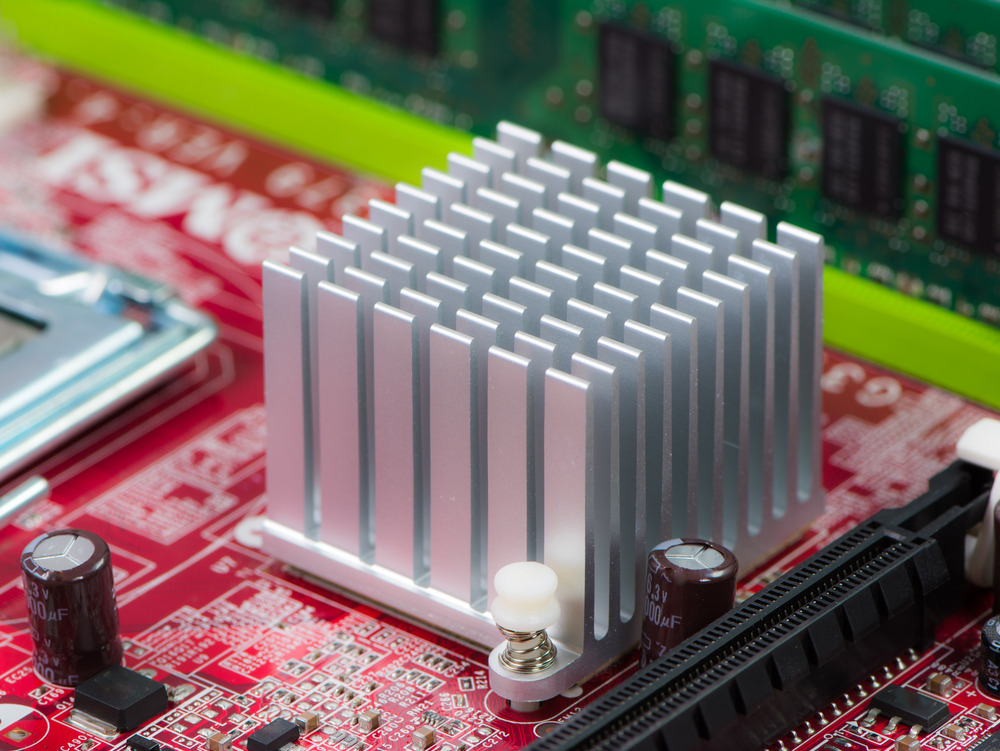

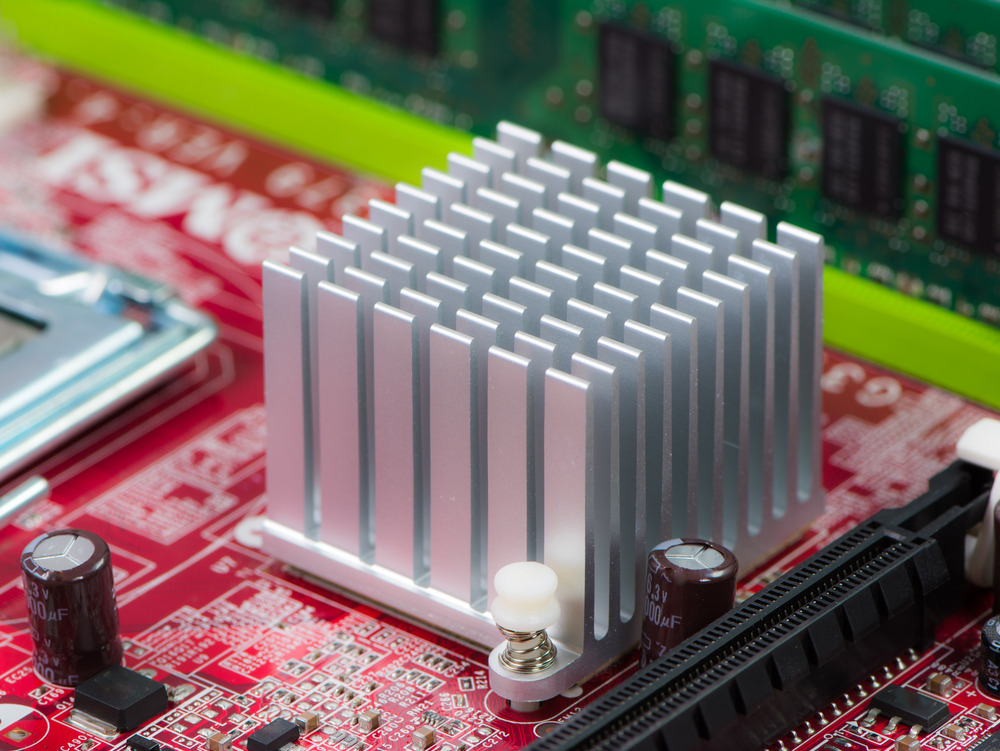

#2 - Heat sinks for cooling CPU's and graphics processors

The heavy thermal, corrosion and biofouling resistance of aluminium alloys, plus its thermal conductivity, have made them the key material of choice for most commercial heat sinks. These are passive heat exchangers that cool a device (typically a microprocessor or graphics card) by dissipating heat from the device to the environment. Heat sinks come in the form of the copper foil of a circuit board or a separate device, and is attached through a variety of methods including thermally conductive tape or epoxy.

#1 - Construction

A no-brainer really; aluminium is pretty much necessary in construction work! From skylights to bridges and ladders to railings, whether implemented as rods, doors or wiring, the low maintenance and ability to paint, mould and join with other materials leaves little reason to not consider it for your chosen project. We see aluminium daily without even thinking about it, and undoubtedly the use of aluminium angles, tubes and boxes in construction are just a few of its biggest starring roles.